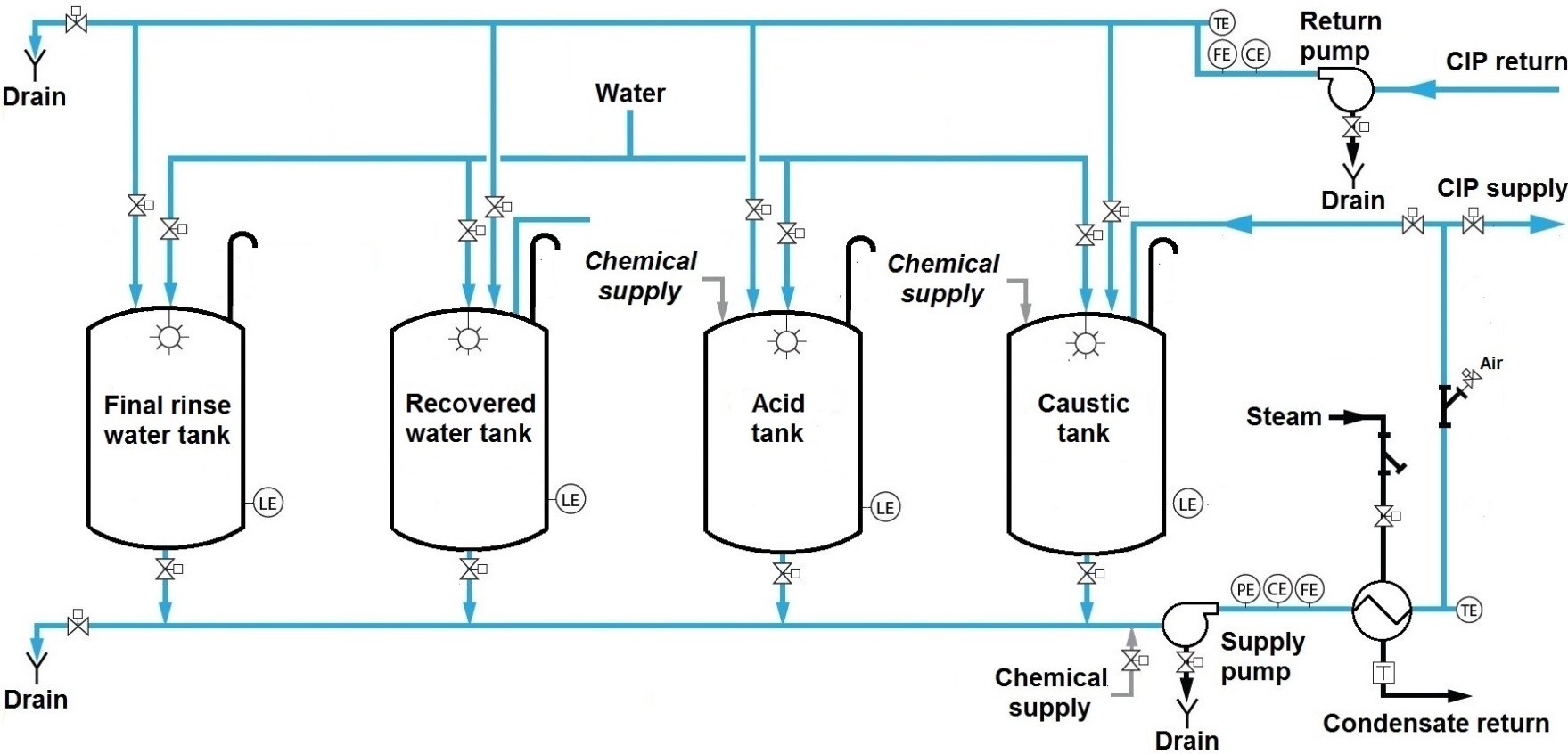

Cleaning in Place (CIP) is an automatically performed cleaning process used to remove residue from complete system components and plumbing circuits without disassembling or opening the system. It is a system of cleaning engineered to provide fast, productive, consistent and reproducible high quality cleaning of all product contact surfaces to a predetermined level of cleanliness, by circulating chemical (detergent and disinfectant) solutions and rinsing water through tanks and piping of a food processing plant that remains assembled in its production configuration, and by jetting or spraying of the product contact surfaces under conditions of increased turbulence and flow velocity.

To clean the whole process equipment and piping system in a minimum of time, a CIP system aims to combine the benefits of high solution temperature (thermal energy) and chemical activity of the detergent chemicals (chemical energy) with the mechanical action caused by the turbulent flow and impact of the sprays/jets of cleaning solution on the equipment surfaces (mechanical energy). But to be successful, other factors are equally important, such as the quality of the water to prepare the cleaning solutions (low counts of spoiling microorganisms, low water hardness), the intimate contact between the cleaning solution and soil (all surface to be cleaned must be covered), the applied CIP program, the hygienic design of the process equipment to be cleaned, and the quality of work of the cleaning staff.