We are Fruit Juice Plant- Juice processing plant manufacturer, supplier and exporter in Gujarat, India. At Raj Innotech Limited, we are offering turnkey solutions for fruit juice plants. Our expertise covers the entire process from fruit processing to juice extraction to high-quality production of fruit juices. We are delivering customized and cost-effective solutions for fruit juice plants – juice processing plants and helping our clients to produce high-quality fruit juices that delight consumers worldwide

For preservation / mixing / dispensing / standardization / and preparation of sugar syrup. Suitable collect, store, dispense and blend liquids like pulp, juice, beverage, sugar syrup....

Read More...

We are the leading manufacturer, supplier, trader and exporter of high Filter Press. These products are manufactured using high quality material and extensively used for filtration purposes...

Read More...

Homogenization is a process which makes the blended beverages having uniform quality. It is not process part of the beverage processing but product specific process...

Read More...

We are Fruit juice plant / Fruit juice processing plant / Juice processing plant manufacturer in Mumbai, Rajkot, India. Using our experience of over 20 years and manufacturing and supplying an exclusive range of fruit juice pasteurizers. In beverage processing / pasteurization plants...

Read More...

Raj Innotech design and manufacture automatic, cost efficient cleaning-in-place (CIP) system used for cleaning process equipment such as filling machines, pasteurizers, sanitary pipes, tanks, plate heat exchanger etc...

Read More...

A plate heat exchanger is a type of heat exchanger that uses metal plates to transfer heat between two fluids. This has a major advantage over a conventional heat exchanger in that the fluids are exposed...

Read More...

Production Speed : 2400 / 3600 / 4400 / 12000 BPH, Capacity : 100 ml to 2000 ml, Neck Dia : 28mm suitable for 35 Bar Air...

Read More...

Inside of bottles are rinsed by spraying water or air or both. Empty bottles move through the inlet neck guide to the spin rinse section. The bottles are held from their neck and inverted by a guide rod along their axis...

Read More...

The cooling tunnel is completely made from the SS material attached with the out feed conveyer by using a buffer conveyor used for getting hot bottles from 90/95 degrees to the room temperature of 28-30 Degrees...

Read More...

Output : Up-to 60 / 90 / 120 BPM, Sleeve LFW : Min-75 mm, Max-165 mm...

Read More...

Supply Voltage : 110 or 220 vac 10%, 50 / 60 Hz, Operating Range : 0 to 45 Deg. C., 10 – 90 % RH non-condensing...

Read More...

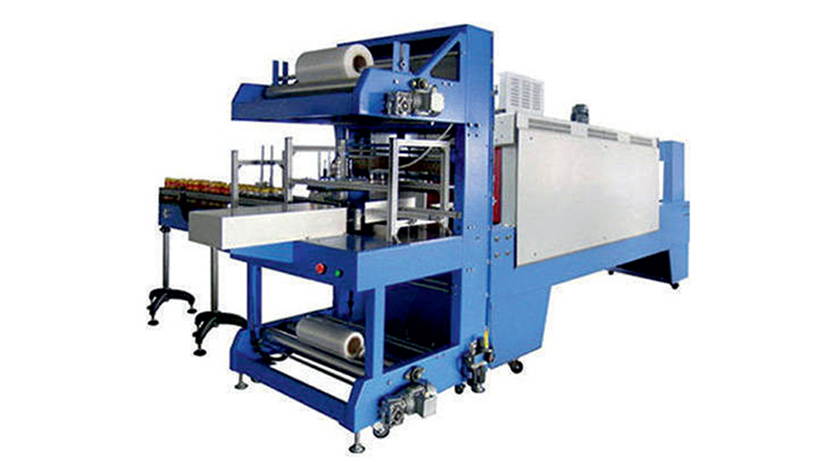

Power Supply : 440v, 3 phase with neutral, Max Film width : 550 mm, Max height of product : 375 mm...

Read More...